commercial@maximuscompletions.com - GST NO. : 24AASCM9330N1ZS

Landing Nipples

Leading Manufacturers, Exporters and Wholesaler of Ported Landing Nipple, Spectramax MF Landing Nipple, Spectramax MORN Landing Nipple and Spectramax MR Landing Nipple from Vadodara.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Finishing | Polished |

| Application | Industrial |

| Size | 1.660" to 41/2" |

| Country of Origin | India |

| Seal Bore I.D. | 1087"3.812" |

| NoGo | 1.135"3.759" |

Preferred Buyer From

| Location | India, United States, Canada, Russian Federation, China, Indonesia |

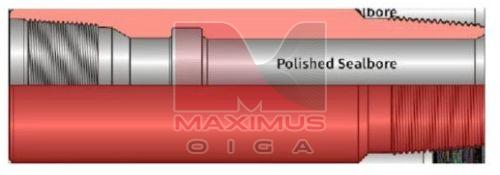

The MR Bottom No Go Non Ported Landing Nipple is a tubing nipple designed for use with bottom no go locking devices only. It features a polished sealbore, a bottom no go shoulder, and a locking groove. This nipple is typically installed at the bottom of the tubing string and is used to locate, seal, and retain flow control accessories with a bottom no go locking device. These accessories are run and retrieved using slickline.

Key Features:

- Polished sealbore for smooth and efficient operation.

- Bottom nogo shoulder ensures accurate placement and sealing.

- Compatible with bottom nogo locking devices.

- Allows easy retrieval and installation using slickline.

Advantages:

- Simple and positive landing of wireline tools.

- Prevents the loss of wireline tools if they are dropped or released during running or retrieving.

Applications:

- Used to land instrument hangers (e.g., bomb hangers).

- Used to land blanking plugs.

- Used to land check (standing) valves.

- Used to land injection valves.

- Used to land chokes.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Application | Industrial |

| Size | 1.660" To 41/2" |

| Country of Origin | India |

| Finishing | Polished |

| Pressure Rating | Up to 10,000 psi |

Preferred Buyer From

| Location | India, United States, Canada, Russian Federation, China, Indonesia |

The Max MF Top No Go, Non Ported Landing Nipple is engineered for high pressure well environments, designed for selective locking of tools using top No Go mechanisms. With a robust polished sealbore, top No Go shoulder, and precise locking groove, this nipple provides reliable retention and engagement of flow control accessories. The versatility of this tool allows for use in various completion settings, ensuring operational efficiency and secure sealing for multiple tools in the same tubing string.

Key Features:

- Features a polished sealbore for enhanced sealing capability

- Compatible with top NoGo locking devices

- Supports multiple sized seal bores on the same tubing string

Advantages:

- Enhances operational efficiency with reliable tool placement

- Reduces the risk of well intervention errors with secure locking mechanisms

- Adaptable to various well conditions, supporting multiple tool configurations

Applications:

- Ideal for securing tools like instrument hangers, blanking plugs, check valves, and injection valves in production wells

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Application | Industrial |

| Size | 1.9" To 6" |

| Country of Origin | India |

| Finishing | Polished |

| Pressure Rating | Up to 10,000 psi |

Preferred Buyer From

| Location | India, United States, Canada, Russian Federation, China, Indonesia |

The Max MORN Bottom No Go Landing Nipple is specifically built for high pressure, non selective operations. With a bottom no go locking design, this tool ensures reliable placement and engagement of flow control accessories. It is designed to withstand extreme well conditions and provides a reliable solution for bottom hole tool deployment. This nipple is particularly useful for applications requiring heavy weight tubing and long term durability in demanding environments.

Key Features:

- Nonselective, bottom nogo profile for flexible tool placement

- Locking groove for secure tool engagement

- Polished sealbore for enhanced sealing in highpressure settings

Advantages:

- Provides precise and reliable placement in highpressure environments

- Reduces risks associated with tool deployment in extreme well conditions

- Ideal for nonselective operations in multiple completion zones

Applications:

- Perfect for the placement of instrument hangers, blanking plugs, check valves, injection valves, and bottom hole chokes in heavyduty application

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Application | Industrial |

| Size | 1.315" To 31/2" |

| Country of Origin | India |

| Finishing | Polished |

| Pressure Rating | Up to 15,000 psi |

Preferred Buyer From

| Location | India, United States, Canada, Russian Federation, China, Indonesia |

The Max MR Landing Nipple is designed for high performance, bottom No Go locking in extreme well environments. Built for heavy duty operations, this landing nipple features a robust polished sealbore and locking groove, ensuring the secure deployment of flow control devices. Its heavy duty construction enables use in high pressure, high temperature wells, delivering operational reliability even in the most demanding environments.

Key Features:

- Robust bottom NoGo profile for secure tool placement

- Polished sealbore for superior sealing performance

- Locking groove designed for highpressure conditions

Advantages:

- Ideal for handling highpressure and hightemperature environments, reducing risks of tool misplacement

- Provides secure locking to prevent loss of tools during operations

- Suitable for both production and intervention operations

Applications:

- Used to land tools such as blanking plugs, instrument hangers, check valves, and injection valves in production and highpressure wells